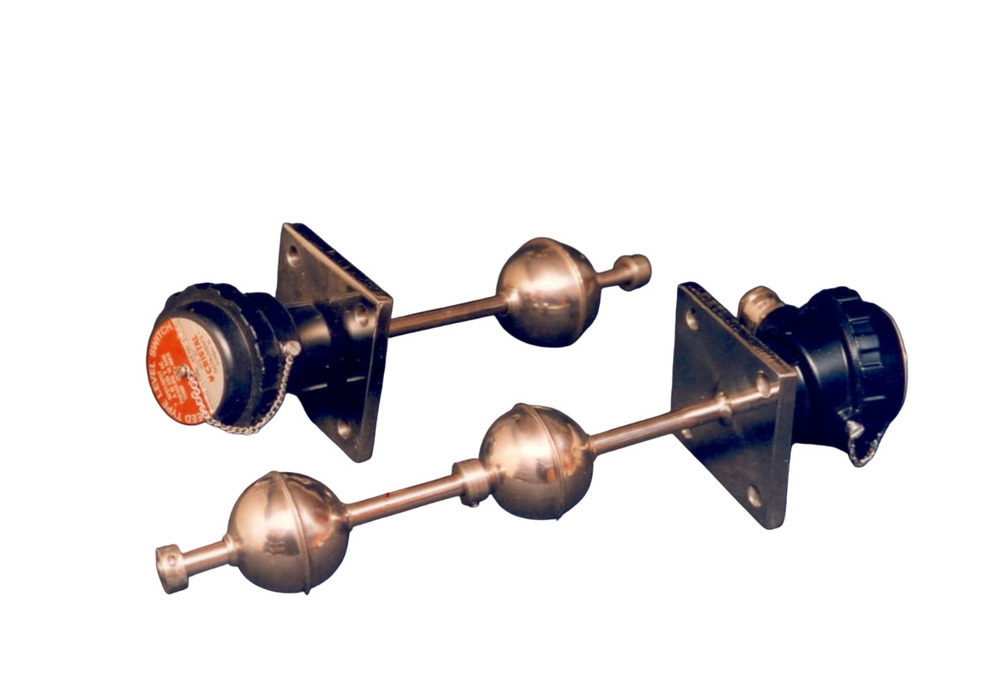

Top Mouned Level Switch

Price 3000 INR/ Unit

Top Mouned Level Switch Specification

- Finish Type

- Polished

- Material

- SS

- Operating Temperature

- As per industry stand Celsius (oC)

- Usage & Applications

- Power Generation Industry , Coal & Steel Industry, Petro- Chemicals, etc.

- Size

- 3 Inch

- Color

- Silver, Black

- Features

- Durable

Top Mouned Level Switch Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Top Mouned Level Switch

Other Details:

Durable Construction

Crafted from stainless steel with a polished finish, this level switch provides excellent resistance to corrosion and mechanical wear. Its resilience makes it ideal for use in harsh industrial environments, ensuring dependable liquid level measurement over an extended service life.

Versatile Industrial Application

Built to cater to the rigorous requirements of power generation, coal & steel, and petrochemical sectors, this switch is engineered to perform efficiently across various processes. It can be easily integrated into existing equipment setups, supporting safety and operational continuity.

FAQs of Top Mouned Level Switch:

Q: How does the Top Mounted Level Switch ensure accuracy in liquid level monitoring?

A: The switch is installed at the top of the tank or vessel and detects the liquid level using internal float mechanisms. Its design minimizes false readings and provides reliable measurement, making it suitable for critical industrial environments.Q: What materials and finishes are available for this level switch?

A: Manufactured from high-quality stainless steel (SS), the switch comes in polished silver or black finishes. This combination ensures resistance to corrosion and enhances the aesthetic appeal, while supporting durability in industrial settings.Q: When should the level switch be maintained or inspected?

A: Regular maintenance should be scheduled according to the operating conditions and standard industry protocols. Inspection intervals may depend on the process environment, liquid type, and frequency of switch activation, ensuring continued optimal performance.Q: Where is this level switch typically used?

A: It is primarily deployed in the power generation industry, coal & steel plants, and petrochemical operations. Its robust design allows safe and efficient monitoring in environments that require reliable liquid level control.Q: What is the installation process for this switch?

A: The switch is mounted on top of the tank or vessel using standardized fittings. Complete installation entails securing the device in place and connecting it to the system controls, following industry safety guidelines and manufacturer recommendations.Q: How does using this level switch benefit industrial operations?

A: Its durable construction and reliable operation reduce the risk of overflows, process interruptions, and safety hazards. By supporting precise liquid level control, it helps maintain operational efficiency and safeguards valuable equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Switch Category

Vibrating Rod Level Switch

Price 12000 INR / Unit

Minimum Order Quantity : 1 Unit

Finish Type : Polished

Size : Various

Usage & Applications : Industrial

Material : SS

Side Mounted Level Switch

Price 3000 INR / Unit

Minimum Order Quantity : 1 Unit

Finish Type : Polished

Size : Various

Usage & Applications : Power Generation Industry , Coal & Steel Industry, Petro Chemicals, etc.

Material : SS

Capacitance Type Level Switch

Minimum Order Quantity : 1 Unit

Finish Type : Polished

Size : Various

Usage & Applications : Power Generation Industry , Coal & Steel Industry, Petro Chemicals, etc.

Material : SS, Plastic

Rotating Paddle Level switch

Minimum Order Quantity : 1 Unit

Finish Type : Polished

Size : Various

Usage & Applications : Power Generation Industry , Coal & Steel Industry, Petro Chemicals, etc.

Material : SS, Plastic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry