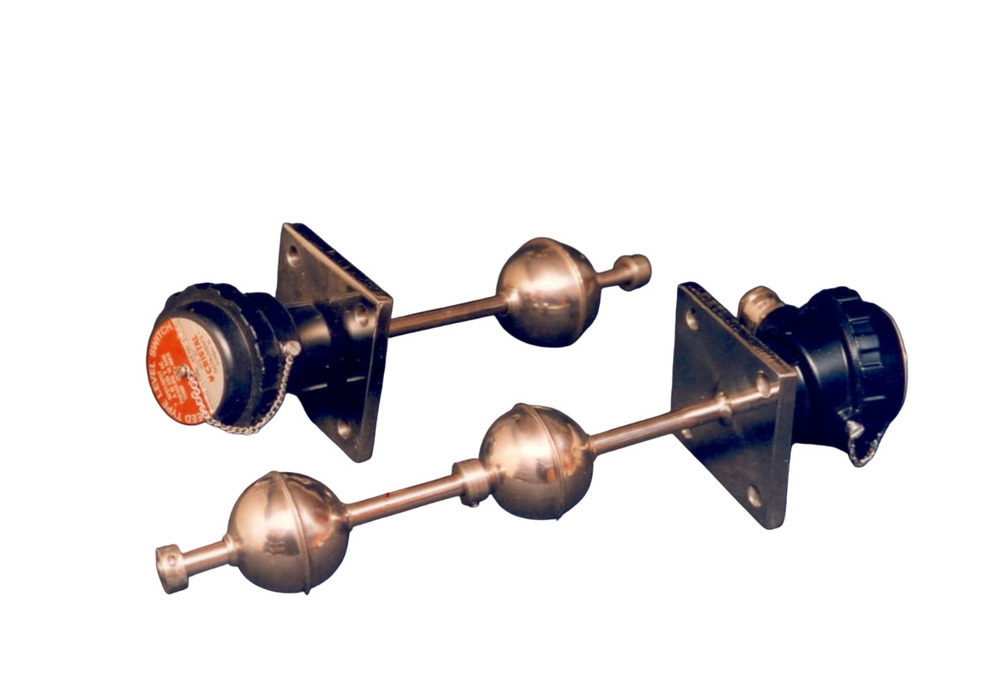

Side Mounted Level Switch

Price 3000 INR/ Unit

MOQ : 1 Unit

Side Mounted Level Switch Specification

- Finish Type

- Polished

- Material

- SS

- Operating Temperature

- 300 DegreeC Celsius (oC)

- Usage & Applications

- Power Generation Industry , Coal & Steel Industry, Petro- Chemicals, etc.

- Size

- Various

- Color

- Silver

- Weight

- Blind square flange 83 mm PCD with 4 bolt holes of 9 mm. 1.0Kg. Kilograms (kg)

- Features

- Durable

Side Mounted Level Switch Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Side Mounted Level Switch

Other Details:

Engineered for High Temperature Applications

Designed to operate efficiently at temperatures up to 300C, the Side Mounted Level Switch excels in harsh industrial settings such as power generation and petro-chemical plants. Its robust stainless steel construction ensures reliability under extreme conditions, safeguarding operational safety and equipment longevity.

Versatile Usage Across Multiple Industries

This level switch is indispensable for the power generation, coal & steel, and petro-chemical sectors. Its adaptability to various tank and vessel sizes makes it an ideal choice for monitoring fluid levels in diverse industrial processes, ensuring consistent and accurate readings.

Precision Manufacturing for Reliable Operation

Manufactured in India with a polished finish, each unit incorporates a blind square flange with precise bolt holes for secure mounting. The switchs design prioritizes durability and low maintenance, making it a favored choice among suppliers and traders for demanding applications.

FAQs of Side Mounted Level Switch:

Q: How is the Side Mounted Level Switch installed in industrial equipment?

A: The switch is fitted via its blind square flange (83 mm PCD) using four 9 mm bolt holes, allowing secure and stable side mounting on tanks or vessels. Installation guidance is typically provided by the supplier or manufacturer.Q: What industries commonly use the Side Mounted Level Switch?

A: This switch is widely utilized in power generation, coal and steel, and petro-chemical industries due to its high-temperature capability and durable stainless steel construction.Q: When should this level switch be chosen over other types?

A: It is ideal for applications where operating temperatures reach up to 300C and where side mounting is preferred for monitoring liquid levels, particularly in challenging industrial processes.Q: Where can replacement parts or new units for the switch be sourced?

A: Replacement units and parts are available through authorized manufacturers, suppliers, and traders across India. Customers can contact these entities for technical support and supply.Q: What is the process for maintaining the Side Mounted Level Switch?

A: Routine maintenance includes visual inspections for wear, ensuring flange bolts are secure, and verifying the functionality. It is designed for low maintenance thanks to its polished stainless steel body.Q: How does the switch improve safety and efficiency in industrial applications?

A: By accurately detecting fluid levels, the switch helps prevent equipment damage and process failures, enhancing safety and optimizing operational efficiency in critical industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Level Switch Category

Vibrating Rod Level Switch

Price 12000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Durable

Size : Various

Operating Temperature : 300 DegreeC Celsius (oC)

Material : SS

Capacitance Type Level Switch

Minimum Order Quantity : 1 Unit

Features : Durable

Size : Various

Operating Temperature : 300 DegreeC Celsius (oC)

Material : SS, Plastic

Rotating Paddle Level switch

Minimum Order Quantity : 1 Unit

Features : Durable

Size : Various

Operating Temperature : 300 DegreeC Celsius (oC)

Material : SS, Plastic

Top Mouned Level Switch

Price 3000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Durable

Size : 3 Inch

Operating Temperature : As per industry stand Celsius (oC)

Material : SS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry